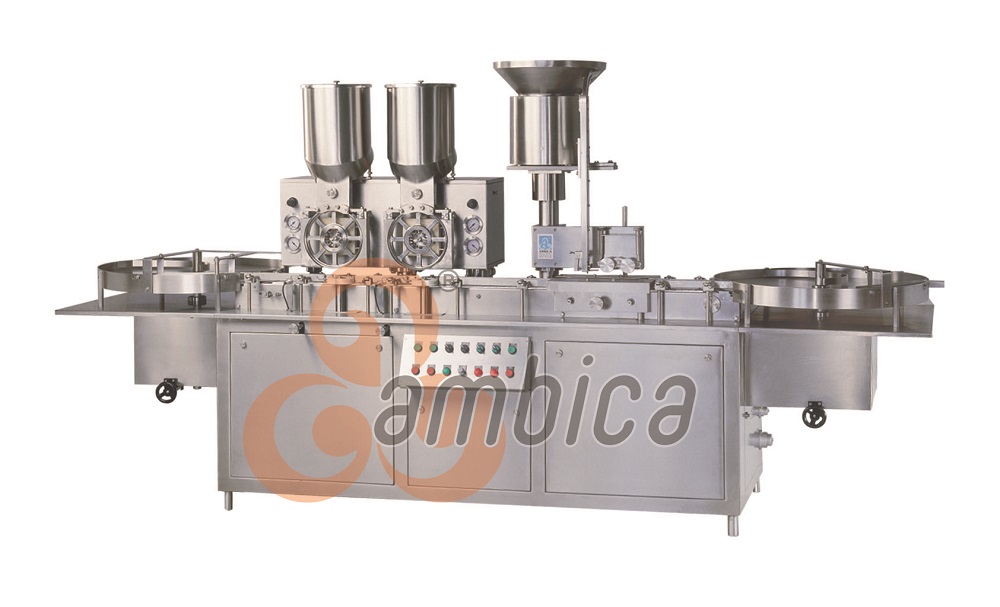

Automatic High Speed Injectable Dry Powder Filling and Eight Heads Injectable Liquid Filling with Rubber Stoppering Machine. Model: AHPF-250DSLF

Automatic High Speed Injectable Dry Powder Filling and Eight Heads Injectable Liquid Filling with Rubber Stoppering Machine. Model: AHPF-250DSLF

The equipment is an automated means to fill sterile dry powder or sterile liquid of different fill volumes in a glass vial and close the same with rubber stopper. It has double head for injectable dry powder filling and eight heads for injectable liquid filling.

This is a servo driven machine and is equipped with vial sampling system and automatic rejection system in case of no rubber stopper on vial.

Product Details

Technical Specifications

12,000 Fills for Single Dose

6,000 Fills for Double Dose

4,000 Fills for Triple Dose

3,000 Fills for Four Dose

10,800 - 12,000 for 5/10 ml Vials

50 mg to 1.5 gm In single dose with help of extra change parts and 1.5 gm to 5 gm by double, triple and four dose depending upon bulk density of powder

0.5 ml to 100 ml

Powder - 5 ml to 30 ml

Liquid - 2 ml to 100 ml

13 mm & 20 mm

Vacuum Disk Based Pick and Place System

4800 mm (L) X 1350 mm (W) X 2100 mm (H) (Approx.)

Salient Features

- Fully automatic injectable dry powder filling, injectable liquid filling and stoppering operation in one machine

- PLC with 10" touch screen HMI for machine control

- Online pre - media filling system

- Safety clutch system to avoid vial breakage

- Flush mounted gauge & regulator for easy setting

- Servo driven rotary piston pumps for liquid filling

- Vial sampling facility before stoppering

- Vial rejection facility in case of no rubber stopper on vial

- 2ml to 50ml liquid filling in single dose and 100ml liquid filling in double dose

- Pick and place type rubber stoppering system for proper placement of stoppers on vial

- Suitable for plain as well as slotted stoppers (for lyophilization), with the help of change parts

- No vial - No fill arrangement- No stopper system

- Change parts of black colored delrin material

- Toughened glass safety cabinet with SS structure

- Separate D.C controller for vibratory rubber stopper bowl

- All contact parts are easily removable for autoclaving / sterilization

- Pure air filters for air and vacuum

- Pre & post gassing system

- An inbuilt real – time speed indicator will show actual speed of machine

- Heavy duty base frame to ensure smooth & vibration free operation

- 3 nos. NVPC ports at customer’s desired location on machine (counters at customer's scope)

Optional Accessories

- Laminar air flow system

- Additional bung feeding system

- Powder loading system above hopper

- Dust extraction unit

- Loadcell based buffer tank

- Liquid recirculation system in buffer tank

- Industrial PC with 21 CFR part 11 compliance SCADA system